Bread Making

By: RedmanShop | February 19, 2025

Introduction

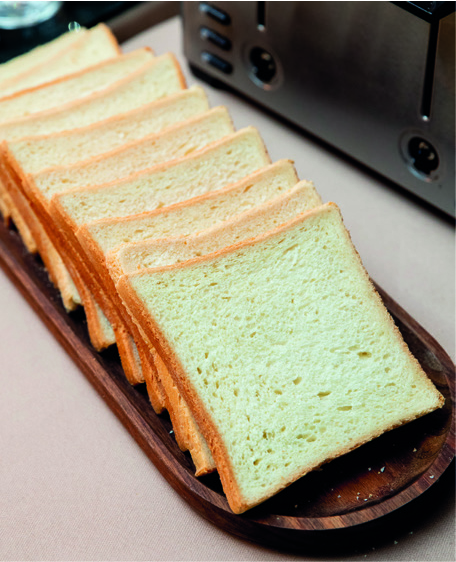

Bread comes in various varieties, shapes, and sizes, using multiple dough-making processes. Straight Dough/No Time and Straight Dough Bulk Fermented are the two most common bread-making processes.

Due to their complexity, this guide does not cover other styles, such as Sponge and Dough, Pre-fermented Doughs, and Autolyse. Successfully mastering the two types mentioned will enable you to explore more complex methods later.

Lean Bread

Flour, Salt, Yeast, Water, Sugar, Fat Bread contains little or no sugar or fats.

Enriched Bread

Flour, Salt, Yeast, Water, Sugar, Fat Bread with an increased level of sugar and fats.

Rich Sweet Bread

Flour, Salt, Yeast, Water, Sugar, Fat, Eggs Bread with higher levels of Sugar, Fats and Eggs to improve softness.

Must Know

All the bread listed can have White or Wholemeal flour as their base or combinations.

Dough Making Methods

Straight Dough/ No Time or Instant dough

Straight Dough means all ingredients are mixed simultaneously to the fully developed stage. “No Time/ Instant” means that the dough does not have a long fermentation time after mixing before processing. After a short rest period, the dough is scaled, rounded, rested, shaped, proofed, and baked. The Baked Bread is available approximately two hours after the weighing, processing, preparation and baking.

Straight Dough / Bulk Fermented

The mixing process is the same as the No Time dough at the mixer stage. The mixed dough is left to stand for its ‘Bulk Fermentation’ period. During this stage, the flour proteins mellow, relax and become more extensible. The length can vary from 45 minutes to two hours or more, depending on yeast levels and the style of bread. The dough is then knocked back (degassed by punching the dough). It is scaled, rounded, rested, shaped, proofed and baked. The Baked Bread is available approximately three to four hours after mixing the dough. The total time will depend on how long the bulk fermentation stage is.

Must Know

Bulk Fermented doughs finish colder and contain less yeast as the longer standing times enable more yeast activity. This activity mellows the flour and lowers the pH resulting in better flavour and a softer internal crumb.

Use of Dough conditioner/ Bread improver

The No Time dough has an added ingredient (Dough conditioner/ bread improver) that quickly mellows the flour proteins as part of the mixing cycle and eliminates the longer fermentation time.

What does this Dough conditioner/ bread improver ingredient do?

Commercial bakers use it in the dough process to strengthen gluten, assist with yeast activity and mellow the gluten quickly. They also contribute to the bread’s shelf life.

Constituents of Dough Conditioner

The dough conditioner/bread improver is the composition of ingredients designed to improve the performance of the flour during the many processing stages and to enhance yeast activity through added yeast foods. These principal components are:

- Ascorbic Acid (as a dough strengthener)

- Enzyme Alpha-Amylase (assists fermentation)

- Emulsifiers work on crumb softness (starch for soft bread) and crust hardness (protein for crusty bread).

Why is the use of a Dough conditioner important?

At the mention of the dough conditioner/ bread improver, many immediately think chemicals can’t be good for us! However, consider them a series of vitamins for the dough designed to enhance its performance and keeping qualities. Humans, after all, take vitamin pills for all sorts of applications and what are they comprised of, if not chemicals?

Ingredients in a Bread Formula

A Basic bread formula consists of Flour, Salt, Yeast and Water. Adding ingredients such as Butter, Eggs, Sugar, Dried fruits and nuts produce softer and moister bread.

Flour – Bread – Wholemeal

High protein flour containing gluten level suitable for bread making. Gluten is the protein in the flour, which gives the dough structure. When you mix flour and water and knead it, you form the gluten (Think chewing gum, which gluten texture is like). The protein level for bread flour is, on average, 12-14%.

You can make 100% wholemeal bread or a mixture with white flour. Singapore’s 20% Wholemeal and 80% White ratio is a typical bread style. In other countries, the balance may be different. Wholemeal flour is now more acceptable to the consumer due to its fine particle size that does not have large bran particles.

Salt

Salt provides flavour, assists in gluten development, and controls fermentation rate (Yeast activity). The trend is towards sea salt instead of common table salt.

Yeast

- Fresh compressed or Instant Active dried (used directly into the dough)

- Active Dried yeast (requires rehydration in warm water before its use)

- Instant Frozen dough yeast, available to commercial bakers

It is a living organism that helps the bread rise; it brings flavour and aroma to many types of bread, depending on the length of fermentation.

- Yeast produces Carbon Dioxide CO2 as part of the fermentation stage, and a by-product of this is alcohol which brings flavours.

- Longer fermentation times result in the development of organic acids, which also provide flavour.

- Yeast is temperature sensitive, requiring water temperatures as a controller.

- Yeast is also sugar sensitive, with two types available in specific dough types.

Yeast Packaging

- Low Sugar – White packaging

- High Sugar – Gold packaging

You will find that as there are many manufacturers, it pays to check the wording on the pack to get the correct one.

Water

Hydrates the flour to form a dough during mixing. The amount will depend on the dough type and flour protein content. Bread flour will hold more water than Plain flour, for example. The water temperature is vital as this will affect the dough temperature after mixing (Finished Dough Temperature).

Regular tap water is acceptable; sometimes, you may need to chill it before using it. While in temperate climates, you will need warmer water during the cooler months.